CNC Milling Services: Precision and Innovation in Modern Manufacturing

CNC Milling Services: Precision and Innovation in Modern Manufacturing

Blog Article

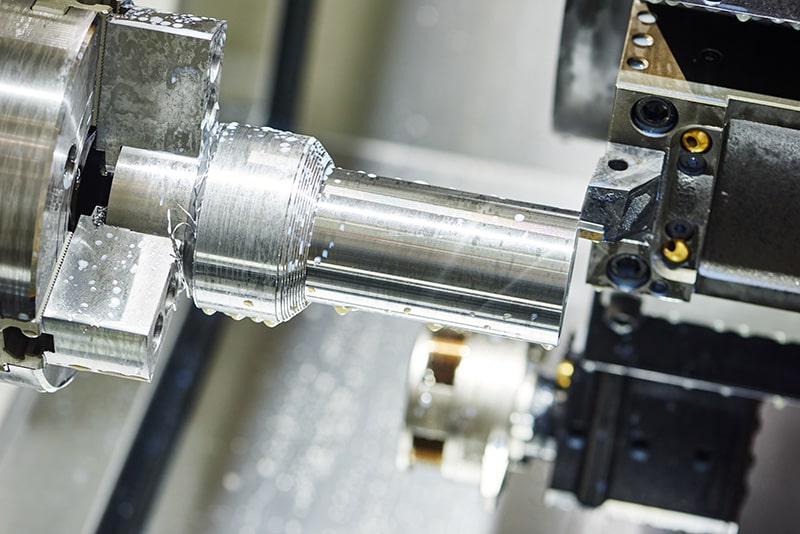

CNC Machining has transformed the manufacturing industry, providing the most precise and effective method for producing components and parts across many industries. This advanced technology uses computers to control machinery that performs cutting and drilling, milling and many other actions on materials such as metals, plastics, and wood. The level of precision achieved by CNC machine is unrivalled that allows intricate designs to be executed with incredible precision. With the replacement of manual work by automation, CNC machines have significantly decreased the chance of human error, and also increased the speed of production. The combination of precision and efficacy has made CNC the machining process a crucial part of modern manufacturing processes.

One of the main benefits of CNC machining is that it has the capability to create highly precise and intricate components that are nearly impossible to make using conventional production methods. CNC machines run on digital drawings, which implies that once a part's design is programmed into the machine, it can be replicated precisely and with consistency. This is especially beneficial in industries like aerospace, automotive, and electronic manufacturing, where accuracy is essential. Additionally, CNC machining is capable of working with an extensive selection of materials, from soft plastics to hard metals. It allows companies to produce parts that meet specific needs for toughness, durability and heat resistance. The flexibility of CNC machining has opened up new possibilities for product design and engineering.

One of the significant advantages of CNC machining is its versatility for working with a diverse range of materials. When it comes to tough metals like steel or titanium, or soft materials such as wood or plastic CNC machines are modified to perform a variety of cutting and shaping tasks. This adaptability makes CNC manufacturing suitable for pieces across a variety of industries that range from medical devices to aerospace components to automotive and consumer electronics. CNC machining is able to produce complex geometries with high precision has also made CNC machines the most popular process for producing intricate parts that are difficult to, if not impossible to make using conventional methods.

Another key benefit to CNC machining effectiveness is its speed. With the help of automation, machining manufacturing companies can drastically cut down the time taken to make parts, which leads to quicker production times and cost savings. Since CNC machines are able to operate all day long with no human oversight, they can increase output without compromising the quality. This degree of automation minimizes the risk of human error, ensuring that every component produced is to all specifications set out within the electronic model. Additionally, CNC machining allows for "lights-out" manufacturing, where machines are still in operation even after employees have gone home to increase productivity, and cutting down on labor costs. To generate additional information please go to Premiumparts

As well as efficiency and speed, CNC machining is valued by its value-for-money, specifically in large-scale production runs. After the initial set-up and programming of the machine is completed making additional parts will require only minimal effort, which reduces manufacturing costs overall. If you are a manufacturer working with costly components like aerospace-grade aluminum, CNC is a method of reducing waste by improving the process of cutting and ensuring that every part is produced with minimal loss of material. Its precision and efficacy make CNC the ideal tool for prototyping as well as full-scale production since it permits manufacturers to quickly test and tweak designs with minimal production cost.

The negative environmental impacts of CNC machine is a different aspect worth considering. Though traditional manufacturing techniques typically generate a significant amount of waste material, CNC machines are known for their material efficiency. With precise cutting and shaping the raw materials used in manufacturing, CNC machining minimizes waste, reducing both material costs and the environmental impact. Additionally, the automation of CNC machines reduces energy consumption compared to manual machining processes. The majority of the modern CNC machines are built with sustainability in mind, employing energy efficient motors and systems to reduce their carbon footprint. This is what makes CNC manufacturing an environmentally-friendly solution for those who want to minimize waste and save resources.